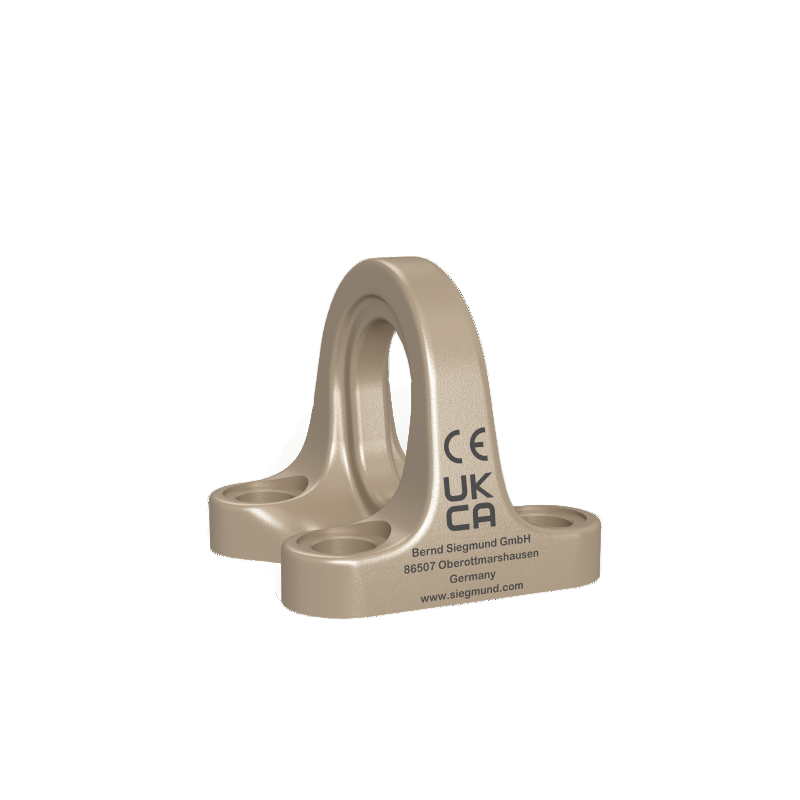

The Siegmund Lifting Lug provides a secure and reliable attachment point for lifting and transporting Siegmund welding tables, U-squares, and perforated plates. Designed for professional shop and industrial use, it ensures safe handling of heavy components with a certified load capacity.

This lifting lug is mounted directly to the welding table using four Siegmund ball clamping bolts in System 28 or 22. Once secured, it allows crane-assisted lifting and precise repositioning of Siegmund equipment.

(DO NOT ATTEMPT TO LIFT ANY MORE WEIGHT THAN WHAT IS SPECIFIED. PLEASE ALWAYS USE THE INDICATED QUANTITY OF BOLTS AND OBSERVE THE LOAD CAPACITY AS WELL AS THE WARNINGS.)

Key Features:

- Heavy-duty construction ensures safe transport of Siegmund welding tables and U-squares.

- Compatible with System 28 using bolts 2-280511 and System 22 using bolts 2-002822.

- Maximum load capacity is 3000 kg (6614 lbs.) in axial pull.

- Diagonal pull at 45° supports 1800 kg (3968 lbs.).

- Certified to EU and UKCA lifting standards for industrial safety.

Specifications:

- Item No.: 2-280836

- System: Siegmund System 28 / 22 Metric Series

- Dimensions: 157x157x147mm (6.18"x6.18"x5.79" Inches)

- Opening Diameter: 78mm (3.07" Inches)

- Weight: 13.2 lbs. (6.0 kg.)

- Material: Heavy-duty steel, certified for lifting use

Safety & Operation:

- The lifting lug must be secured with four Siegmund-approved ball clamping bolts torqued to specification.

- For System 28, tightening torque is 25 Nm (18.4 ft-lbs.).

- For System 22, tightening torque is 15 Nm (11.1 ft-lbs.).

- Always perform a visual inspection before each use to confirm integrity and proper bolt function.

- Only trained and authorized personnel may operate lifting equipment.

- Loads must never be lifted higher than necessary, and no personnel may stand beneath suspended loads.

- The lifting lug may not be used for transporting non-Siegmund components.

Common Uses:

The lifting lug is used to mount table legs by lifting the table-top. It supports relocation of welding tables, perforated plates, or U-squares within the shop. It provides safe and stable crane-assisted handling of heavy Siegmund components during fabrication and assembly.